Our areas of expertise

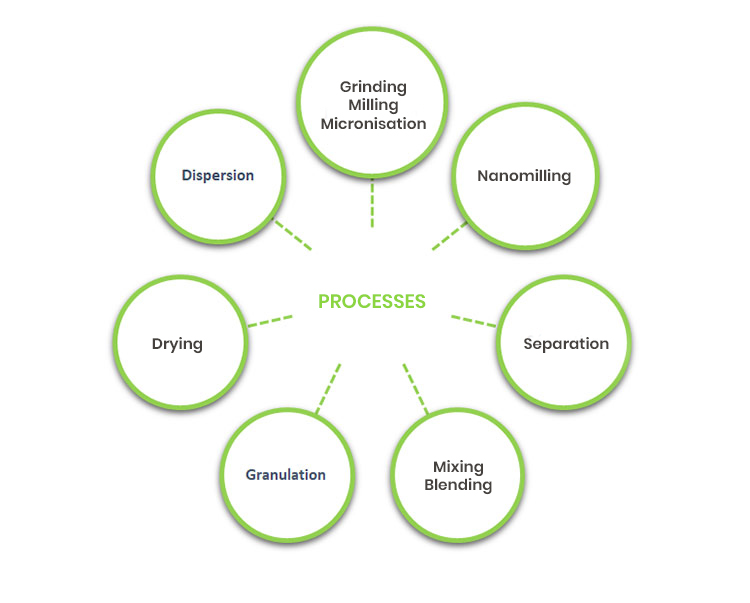

Our team of experts brings to you experience in powder processing, whether in dry or liquid environments, from laboratory to industrial scale. Our in-depth knowledge of characterisation techniques will be a key asset for understanding operations and evaluating performance.

Produce more, Produce cheaper

Enhancing Production Capacities and Throughput While Reducing Costs. These are the primary goals of Production services, and POUDRES DURABLES is here to help you achieve them.

Our experts can assist you with a variety of missions, including :

- Audit of production lines

- Process optimisation

- Optimisation of the sequence of unit operations

- Equipment modifications or support for acquiring suitable equipment

- Instrumentation of the production line

- Process control through on-line measurement

- Workshop revamping

- Technology transfer

POUDRES DURABLES implements a comprehensive analysis at the plant level, combined with detailed assessments of individual unit operations. By cross-referencing data and applying a methodology tailored to the powder domain, we ensure effective optimisation of your entire production process.

Equipment acquisition support

How to select the most suitable equipment for your product and specifications ?

Choosing the right mill or microniser for your project can be a daunting task. With a vast range of equipment and manufacturers available, it is challenging to identify the optimal solution.

Various classification systems have been proposed—based on particle size range, equipment scale, industry sector, or operational constraints. However, navigating these options and scaling up from laboratory to industrial applications remains complex.

This observation can be repeated more widely for other equipment such as wet grinding, mixing and blending, separating, or shaping systems.

Guidance and Assistance

Based on more than 20 years of experience in the field, we are able to set up a methodology specific to your project. Starting with your existing installations (laboratory, pilot, or industrial equipment) and leveraging our knowledge of suppliers and testing centres, we design a customised approach that aligns with your objectives and resources.

We provide support for testing and for the physical characterisation of powders.

Scaling Up : From Feasibility to Industrial Units

Surrounded by specialists in the field of powders and processes, we assist you through every phase of your project :

- Exploratory phase : search for the best equipment to achieve the objectives

- Pilot demonstrator phase :

- Development, qualification and production of pilot equipment

- Validation of performance (productivity, energy, maintenance, etc.)

- Dimensioning and engineering of industrial installations

- Opex and Capex estimate

- Industrial phase :

- Qualification and performance analysis

- In-line particle size control

- Staff training.

At every stage, POUDRES DURABLES ensures a methodical and efficient approach to help you achieve optimal performance and meet your production goals.

Energy Optimisation

Comminution operations (crushing, grinding, micronisation) account for 10% of global energy consumption. The energy efficiency of comminution installations is notoriously low. According to researchers, less than 3% of the energy used during grinding is effectively dedicated to particle size reduction. Losses such as heat and noise are typical in grinding workshops.

Optimising the energy performance of comminution installations is therefore a critical challenge.

Our Approach to Energy Optimisation

POUDRES DURABLES conducts both a macro-level analysis at the factory scale and a micro-level analysis for individual machines or unit operations. By combining macro and micro data with a methodology tailored to the powder industry, we can effectively optimise the entire production system.

Our objectives :

- Energy optimisation : Reduce energy consumption.

- Production optimisation : Increase throughput.

- Streamlining unit operations : Rationalise the production process.

- Qualification and optimisation of recirculation loops.

- Energy recovery : Repurpose energy for sanitary hot water, process heating, or heating adjacent offices or workshops.

This methodology can also be applied to other energy-intensive powder operations, such as granulation, agglomeration, or mixing.

Audit and Methodology

After signing a confidentiality agreement, POUDRES DURABLES works with you to define the scope and objectives of the project.

We base our approach on your existing data (process flow diagrams, facility layouts, energy bills, energy management practices, operating conditions) as well as measurements collected specifically for the audit (energy usage, in-line particle size measurements, and customised instrumentation).

The audit report will provide actionable insights tailored to your constraints, context, and needs, including :

- Opportunities for improvement.

- Cost-savings or performance gains.

- Required investments.

- ROI (Return on Investment).

Support : Solutions and Implementation

Following the audit, POUDRES DURABLES offers detailed pre-project studies for energy recovery solutions and can oversee implementation or deliver a turnkey system.

For powder process optimisation, we can assist as a Project Owner’s Representative (Assistant to the Owner) to manage the necessary actions for processes, including upgrades, adjustments, or equipment replacement/addition.

Towards Industry 4.0

We go further by supporting your transition to Industry 4.0 :

- Instrumentation of installations : Enhance monitoring capabilities.

- Optimisation through on-line measurement : Improve process control.

- On-site or remote process management : Enable efficient and responsive operations.

By combining expertise in powder processes with advanced methodologies, POUDRES DURABLES helps you achieve optimal energy efficiency and sustainable production.