Cosmetic products are complex formulations. Creams, deodorants, shampoo, make-up... most of them contain at least one ingredient in powder form.

These ingredients must be carefully selected, dosed, and blended to ensure their efficacy and safety. The texture, application, durability, and color uniformity are determined not only by the formula but also by the manufacturing technologies and parameters (grinding, sieving, micronisation, mixing, dispersion).

With the growing consumer demand for more eco-friendly products in "solid" formats, powdered cosmetics are becoming increasingly important on the market. They require specific industrial equipment and expertise to address challenges such as mixing or blending, particle size, density, durability, and pulverulence.

Beyond functional properties, cosmetic products must comply with strict hygiene standards and adhere to relevant regulations.

As powder experts, POUDRES DURABLES contribute to your innovations from laboratory scale to industrialisation.

Based on your unique needs, we can support you in a wide range of areas across your organization :

Production

Produce more, produce cheaper

- Optimise production capacity

- Increase production throughput

- Optimise energy efficiency

- Calculate Opex and Capex for plant optimisation

- Optimise process diagrams by integrating unit operations

- Control installations with online particle size measurement to optimise production

- Compensate for energy input from grinders, dryers, fluidized beds

- Optimise separation and sorting of components by nature, composition or colour

- Minimise waste and scrap

- Incorporate recycled material

Revamp

- Customise existing installations : modernise, instrument, etc

- Upgrade or Revamp installations

- Evolve towards Industry 4.0

Instrument, Automate, Control

- Instrument the powder installations

- Monitor particle size in real-time (Insitec, Parsum, etc.)

- Control production through online measurement

Scale-up, Industrialise and Transfer

- Choose the best grinder, mill, microniser, sieve, mixer, blender, granulator, dryer, etc.

- Calculate OPEX and CAPEX for future facilities to optimise equipment choices

- Optimise the purchase of laboratory, pilot or industrial equipment

Produce more consistently, without variation

- Manage analysis and control for optimised plant operation

- Optimise sampling techniques

- Control raw materials (Analytics method)

- Minimise drift

- Optimise cleaning and maintenance cycles

- Optimise the selection of raw materials

- Control equipments using online granulometry to stabilise production

Preserve product quality

- Reduce waste and scrap

- Ensure batch homogeneity (raw materials, finished products)

Ensure safe operations

- Improve installations safety : adapt strategy to product-specific risks (Atex compliance)

- Control dust and pulverulent powders emissions

- Ensure proper inerting of equipment

- Handle micro and nano powders safely

Support the client

- Commission powder production facilities

- Train teams on powder-specific challenges

- Provide training for operating : grinding, micronisation, sieving, drying, mixing, etc.

- Assist with project management and owner support

Innovation, Strategy, R&D

Innovation

- Sort and Separate components

- Innovate in powders, processes and technologies

- Particle design

- Grow your business by expanding your product range

- Identify new opportunities and solutions through innovation

- Recycle powders

- Incorporate recycled materials

Scale-up and Development : From R&D to Industrial production

- Scale-up from R&D laboratories to pilot and industrial production

- Design and Size installations

- Calculate OPEX and CAPEX for future installations to optimise equipment selection

- Optimise energy consumption for a production line or the entire plant

Research : Powders strategy

- Optimise the procurement of laboratory equipment

- Choose equipment such as grinders or any powder-related machinery tailored to the product and specifications

- Grow your business by diversifying your product portfolio

Analysis, Control and Characterisation

- Control particle size analysis in the laboratory

- Characterise powders (particle size, rheology, specific surface area, porosity, morphology, etc.)

- Ensure batch homogeneity (raw materials, finished products)

- Determine the state of the blend

- Control the properties of use or the end-use properties of powders

- Optimise sampling techniques

- Control the granulometry directly on the production line

QHSE : Quality, Health, Safety and Environment

Quality

- Improve production quality

- Reduce non-conformities through on-line particle size control

- Protect products from oxidation (quality inerting)

- Correct deviations through on-line particle size control

Hygiene

- Optimise the cleanability of equipments and premises

- Control dust and pulverulent powders emissions

Safety

- Ensure installations safety : adapt strategy to product-specific risks (Atex compliance)

- Control the handling of micro and nano powders

- Take the “Process” into account in the Atex strategy

- Use industrial gases as a preventive barrier against explosions (safety inerting)

- Control dust and pulverulent powders emissions

- Control the inerting processes for installations

Environment

- Recycle materials

- Reduce energy consumption of production lines or the whole plant

- Sort, separate, reuse materials (recycling and circular economy)

- Control dust and pulverulent powders emissions

Cosmetic Industry is going green

Managing environmental impact has become a major challenge in the development of products and manufacturing processes. Cosmetic companies are now turning to more efficient manufacturing techniques, seeking to replace certain raw materials… The galenic formulation is becoming more "Green," and processes are focusing on eco-efficiency.

Thanks to its expertise in the physical characterisation of divided solids (granulometry, morphology, surface area, porosity, flowability...), POUDRES DURABLES can assist you substitute your raw materials to switch to biosourced alternatives.

POUDRES DURABLES can also support you in optimising your processes, including grinding, micronisation, dispersion, wet grinding, mixing, granulation, and dynamic separation. Energy optimisation and waste reduction through process control are key areas where POUDRES DURABLES can help you improve your environmental footprint.

Our Missions

Audit of « powder » process

Based on its experience in the field of divided solids, POUDRES DURABLES offers its expertise in the implementation of specific solutions. Below are some examples of projects carried ou in the Cosmetic industry :

- Grinding, mixing, granulation : optimization of the manufacturing steps

- Formulation and mixing of dry powders : improvement of flow properties

- Liquid milling and nano-milling : controlling suspensions

- Selection of mixer and other production equipment

- Qualification of Raw materials : sourcing and homogeneity

- Installation audit : improving productivity

- Reduce nitrogen consumption on a cryogenic or inerted installation

- Optimise cleanibility of the installations

- How to control the powdering of products

- Mottage and powder vaulting : finding and adapting solutions to the production line

- Optimise mixing time with an in-situ probe

- Moving towards Industry 4.0

Wherever granules, powders, or colloids are involved, we can assist with the characterisation of divided solids (either in your laboratory or online) and with the processes for powder production and shaping (such as atomisers, grinders, micronisers, granulators, mixers, blenders, fluidised air bed, etc).

On-Line Sampling and Measurement, using an Insitec and a Parsum probe

Our Trainings

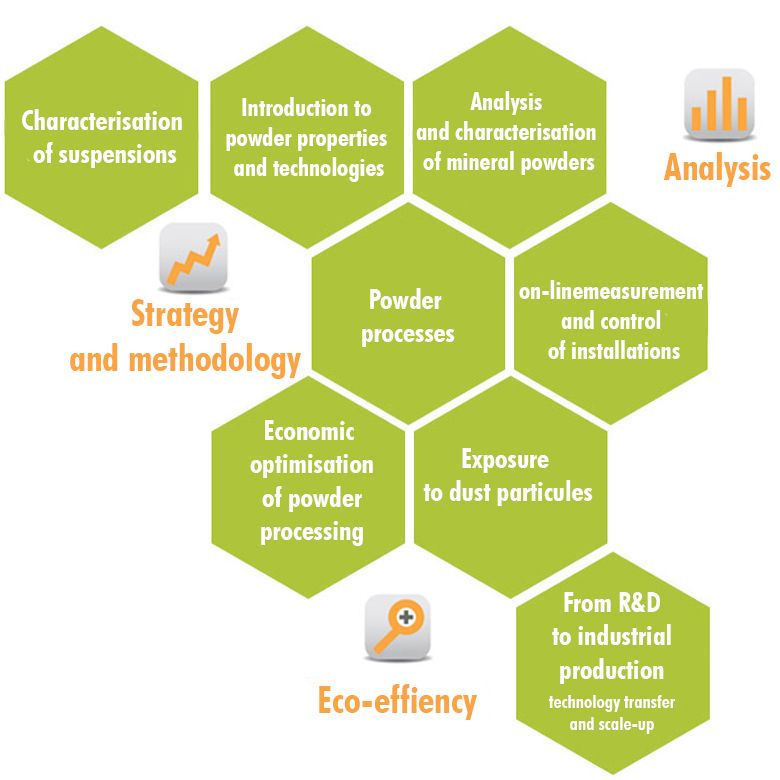

Poudres Durables can provide you and your team with unique training courses, designed to address your specific needs within the HealthCare industry.

Find out more on our training courses in the field of divided solids :

Process and Production

Innovation, strategy and R&D

Powder analysis, control and characterization

Quality Hygiene Safety and the environment of powders

Overview of the world of powders