Whether in automotive, electronics, packaging, healthcare, or aerospace, polymers (thermoplastics, thermosets, elastomers) are produced in the form of powders, granules, or semi-finished products.

Mixing, grinding, cryo-milling, micronisation, and separation operations must be optimised to ensure flowability, homogeneity, reactivity, and other key properties.

Composite materials result from the combination of several materials, providing superior performance compared to individual materials. They are most commonly used for their strength, lightness, and longevity.

Composites have thus become widespread across all industries : boating, aerospace, automotive, wind energy, sporting goods, construction, and more.

The final properties of composite materials depend on the materials chosen for assembly (matrix and reinforcements), which makes it possible to design “tailor-made” materials based on the targeted technical and economic performance.

Raw materials can be in the form of divided solids :

Polymers (natural, synthetic, artificial, recycled...) in powder or granule form

Reinforcements that provide the structure of the material, in the form of fibres (glass, carbon, aramid, or natural fibres) or particles

Fillers and additives, in powder form, have variable functions : compression strength and lightweighting (glass microspheres), coloration, wear and UV resistance (carbon black), insulation (silica), electrical and thermal conductivity (metallic particles), etc.

To achieve the desired technical performance for composites, it is crucial to control all stages of the manufacturing process, starting with the raw materials. The physical properties of the incorporated powders (size, shape, specific surface area, homogeneity, etc.) have an impact both on the quality and ease of processing of the composites, as well as their functional properties.

With the growth of composite production, recycling and valorisation of these materials is a major challenge. Grinding and separation processes are among the mechanical solutions for recycling.

Based on your unique needs, we can support you in a wide range of areas across your organization

Production

Produce more, produce cheaper

- Optimise production capacity

- Increase production throughput

- Optimise energy efficiency

- Calculate Opex and Capex for plant optimisation

- Optimise process diagrams by integrating unit operations

- Control installations with online particle size measurement to optimise production

- Compensate for energy input from grinders, dryers, fluidized beds

- Optimise separation and sorting of components by nature, composition or colour

- Minimise waste and scrap

- Incorporate recycled material

Revamp

- Customise existing installations : modernise, instrument, etc

- Upgrade or Revamp installations

- Evolve towards Industry 4.0

Instrument, Automate, Control

- Instrument the powder installations

- Monitor particle size in real-time (Insitec, Parsum, etc.)

- Control production through online measurement

Scale-up, Industrialise and Transfer

- Choose the best grinder, mill, microniser, sieve, mixer, blender, granulator, dryer, etc.

- Calculate OPEX and CAPEX for future facilities to optimise equipment choices

- Optimise the purchase of laboratory, pilot or industrial equipment

Produce more consistently, without variation

- Manage analysis and control for optimised plant operation

- Optimise sampling techniques

- Control raw materials (Analytics method)

- Minimise drift

- Optimise cleaning and maintenance cycles

- Optimise the selection of raw materials

- Control equipments using online granulometry to stabilise production

Preserve product quality

- Reduce waste and scrap

- Ensure batch homogeneity (raw materials, finished products)

Ensure safe operations

- Improve installations safety : adapt strategy to product-specific risks (Atex compliance)

- Control dust and pulverulent powders emissions

- Ensure proper inerting of equipment

- Handle micro and nano powders safely

Support the client

- Commission powder production facilities

- Train teams on powder-specific challenges

- Provide training for operating : grinding, micronisation, sieving, drying, mixing, etc.

- Assist with project management and owner support

Innovation, Strategy, R&D

Innovation

- Sort and Separate components

- Innovate in powders, processes and technologies

- Particle design

- Grow your business by expanding your product range

- Identify new opportunities and solutions through innovation

- Recycle powders

- Incorporate recycled materials

Scale-up and Development : From R&D to Industrial production

- Scale-up from R&D laboratories to pilot and industrial production

- Design and Size installations

- Calculate OPEX and CAPEX for future installations to optimise equipment selection

- Optimise energy consumption for a production line or the entire plant

Research : Powders strategy

- Optimise the procurement of laboratory equipment

- Choose equipment such as grinders or any powder-related machinery tailored to the product and specifications

- Grow your business by diversifying your product portfolio

Analysis, Control and Characterisation

- Control particle size analysis in the laboratory

- Characterise powders (particle size, rheology, specific surface area, porosity, morphology, etc.)

- Ensure batch homogeneity (raw materials, finished products)

- Determine the state of the blend

- Control the properties of use or the end-use properties of powders

- Optimise sampling techniques

- Control the granulometry directly on the production line

QHSE : Quality, Health, Safety and Environment

Quality

- Improve production quality

- Reduce non-conformities through on-line particle size control

- Protect products from oxidation (quality inerting)

- Correct deviations through on-line particle size control

Hygiene

- Optimise the cleanability of equipments and premises

- Control dust and pulverulent powders emissions

Safety

- Ensure installations safety : adapt strategy to product-specific risks (Atex compliance)

- Control the handling of micro and nano powders

- Take the “Process” into account in the Atex strategy

- Use industrial gases as a preventive barrier against explosions (safety inerting)

- Control dust and pulverulent powders emissions

- Control the inerting processes for installations

Environment

- Recycle materials

- Reduce energy consumption of production lines or the whole plant

- Sort, separate, reuse materials (recycling and circular economy)

- Control dust and pulverulent powders emissions

Liquid Nitrogen : a solution for grinding Polymers

POUDRES DURABLES can offer its recognised expertise in the use of industrial gases. Depending on your product, we can help you make the most of cryogenic fluid applications.

Elastomers and thermoplastics are particularly difficult to grind because they deform during grinding. Cryogenic grinding is made possible by the use of liquid nitrogen. It makes it possible to :

- Grind the polymer below its glass transition temperature (Tg), ensuring it remains in a vitreous, rigid state. This makes it more brittle, weakened, and easier to crush.

- Compensate for the heat generated during grinding, especially with materials that are difficult to process. This prevents overheating and improves productivity.

- Monitor the temperature to prevent dangerous decomposition reactions or the degradation of temperature-sensitive polymers.

- Treat moisture-sensitive materials : the evaporation of liquid nitrogen creates a nitrogen atmosphere, protecting the material from moisture exposure.

Our Missions

Audit of « powder » process

Based on its experience in the field of divided solids, POUDRES DURABLES offers its expertise in the implementation of specific solutions. Below are some examples of projects carried ou in the Polymers and Composites industries :

- Liquid milling and nano-milling : controlling suspensions

- Crushing, Shredding, Grinding, Micronising, sorting : optimisation of the process diagram

- Formulation and blending of dry powders : improving flow properties

- Optimise cryogenic milling and Control granulometry

- Support in the acquisition of separation equipment

- Selection of the grinder and other equipment : scale-up

- Revamping/refurbishment of a grinder installation

- Reduce nitrogen consumption on a cryogenic or inerted installation

- Online particle size measurement : from measurement to piloting of the installation

- Moving towards Industry 4.0

Wherever granules, powders, or colloids are involved, we can assist with the characterisation of divided solids (either in your laboratory or online) and with the processes for powder production and shaping (such as atomisers, grinders, micronisers, granulators, mixers, blenders, fluidised air bed, etc).

On-Line Sampling and Measurement, using an Insitec

Our Trainings

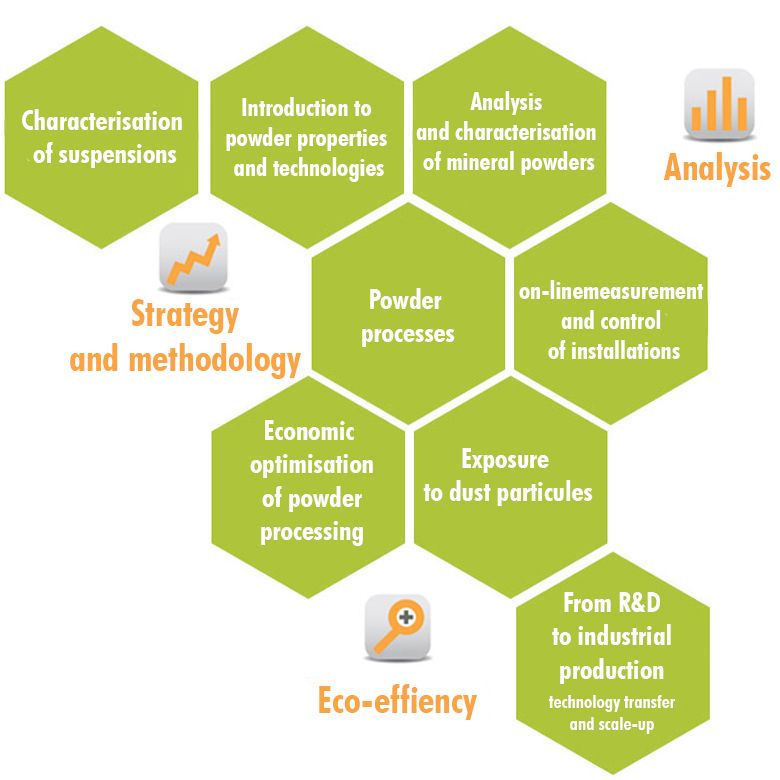

POUDRES DURABLES can provide you and your team with unique training courses, designed to address your specific needs within the Polymers and Composites industries.

Find out more on our training courses in the field of divided solids :

Process and Production

Innovation, strategy and R&D

Powder analysis, control and characterization

Quality Hygiene Safety and the environment of powders

Overview of the world of powders