Mineral powders are present in many industrial sectors. Each material is associated with highly specific objectives, which require expertise in the stages of the division and separation : crushing, grinding, micronisation, separation and/or sieving.

Controlling the physical characteristics of powders is essential to ensure their functional properties or properties of use, such as reactivity, flowability, mechanical strength, colour, filtering capacity, etc.

The specificities of these powders depend on the application field : paints, pigments, coatings, paper, construction materials, water treatment, graphite, carbonates, lime, cement, batteries, etc.

Based on your unique needs, we can support you in a wide range of areas across your organization

Production

Produce more, produce cheaper

- Optimise production capacity

- Increase production throughput

- Optimise energy efficiency

- Calculate Opex and Capex for plant optimisation

- Optimise process diagrams by integrating unit operations

- Control installations with online particle size measurement to optimise production

- Compensate for energy input from grinders, dryers, fluidized beds

- Optimise separation and sorting of components by nature, composition or colour

- Minimise waste and scrap

- Incorporate recycled material

Revamp

- Customise existing installations : modernise, instrument, etc

- Upgrade or Revamp installations

- Transition towards Industry 4.0

Instrument, Automate, Control

- Instrument the powder installations

- Monitor particle size in real-time (Insitec, Parsum, etc.)

- Control production through online measurement

Scale-up, Industrialise and Transfer

- Choose the best crusher, grinder, microniser, sieve, mixer, granulator, dryer, etc.

- Calculate OPEX and CAPEX for future facilities to optimise equipment choices

- Optimisie the purchase of laboratory, pilot or industrial equipment

Produce more consistently, without variation

- Manage analysis and control for optimised plant operation

- Optimise sampling techniques

- Control raw materials (Analytics method)

- Minimise drift

- Optimise cleaning and maintenance cycles

- Optimise the selection of raw materials

- Control equipments using online granulometry to stabilise production

Preserve product quality

- Reduce waste and scrap

- Ensure batch homogeneity (raw materials, finished products)

Ensure safe operations

- Improve installations safety : adapt strategy to product-specific risks (Atex compliance)

- Control dust and pulverulent powders emissions

- Ensure proper inerting of equipment

- Handle micro and nano powders safely

Support the client

- Commission powder production facilities

- Train teams on powder-specific challenges

- Provide training for operating : grinding, micronisation, sieving, drying, mixing, etc.

- Assist with project management and owner support

Innovation, Strategy, R&D

Innovation

- Sort and Separate components

- Innovate in powders, processes and technologies

- Particle design

- Grow your business by expanding your product range

- Identify new opportunities and solutions through innovation

- Recycle powders

- Incorporate recycled materials

Scale-up and Development : From R&D to Industrial production

- Scale-up from R&D laboratories to pilot and industrial production

- Design and Size installations

- Calculate OPEX and CAPEX for future installations to optimise equipment selection

- Optimise energy consumption for a production line or the entire plant

Research : Powders strategy

- Optimise the procurement of laboratory equipment

- Choose equipment such as grinders or any powder-related machinery tailored to the product and specifications

- Grow your business by diversifying your product portfolio

Analysis, Control and Characterisation

- Control particle size analysis in the laboratory

- Characterise powders (particle size, rheology, specific surface area, porosity, morphology, etc.)

- Ensure batch homogeneity (raw materials, finished products)

- Determine the state of the blend

- Control the properties of use or the end-use properties of powders

- Optimise sampling techniques

- Control the granulometry directly on the production line

QHSE : Quality, Health, Safety and Environment

Quality

- Improve production quality

- Reduce non-conformities through on-line particle size control

- Protect products from oxidation (quality inerting)

- Correct deviations through on-line particle size control

Hygiene

- Optimise the cleanability of equipments and premises

- Control dust and pulverulent powders emissions

Safety

- Ensure installations safety : adapt strategy to product-specific risks (Atex compliance)

- Control the handling of micro and nano powders

- Take the “Process” into account in the Atex strategy

- Use industrial gases as a preventive barrier against explosions (safety inerting)

- Control dust and pulverulent powders emissions

- Control the inerting processes for installations

Environment

- Recycle materials

- Reduce energy consumption of production lines or the whole plant

- Sort, separate, reuse materials (recycling and circular economy)

- Control dust and pulverulent powders emissions

Size reduction and Shaping of mineral powders

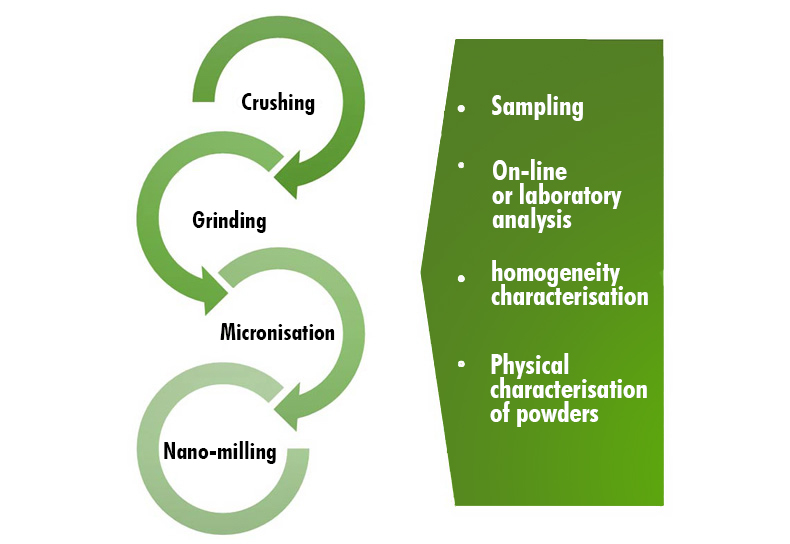

From Crushing to Nanomilling

For all size reduction processes (crushing, grinding, micronisation, nano-milling), POUDRES DURABLES has developed strategies and methods based on in-depth knowledge of the processes, sampling principles and the techniques for characterising divided solids, both on-line and in the laboratory.

Mixing, Granulation, Agglomeration, Coating, Encapsulation, Separation...

Once their size has been reduced, mineral powders can be processed in further stages :

- Mixed and shaped (agglomerated, granulated, etc.)

- Fractionated for enrichment purposes (grinding/separation)

- Separated for size control.

Our Missions

Audit of « powder » process : wear and abrasion protection of powders

Based on its experience in the field of divided solids, POUDRES DURABLES offers its expertise in the implementation of specific solutions. Below are some examples of projects carried ou in the minerals industry :

- Crushing, grinding, micronising : optimising the production diagram

- Liquid milling and nano-milling : controlling suspensions

- Formulation and blending of dry powders : improving flow properties

- Help in selecting the optimum separation technique

- Optimisation and control of product particle size

- Selection of mills and other production equipment : scaling up

- Grinder refurbishment

- Plant audit : improving productivity

- Energy audit : recovering heat from the process to optimise the plant

- How to control the powderiness of products

- Optimising mixing time with an in-situ probe

- In-line granulation and particle size measurement

- Moving towards Industry 4.0

On-Line Sampling and Measurement, using an Insitec

Our Trainings

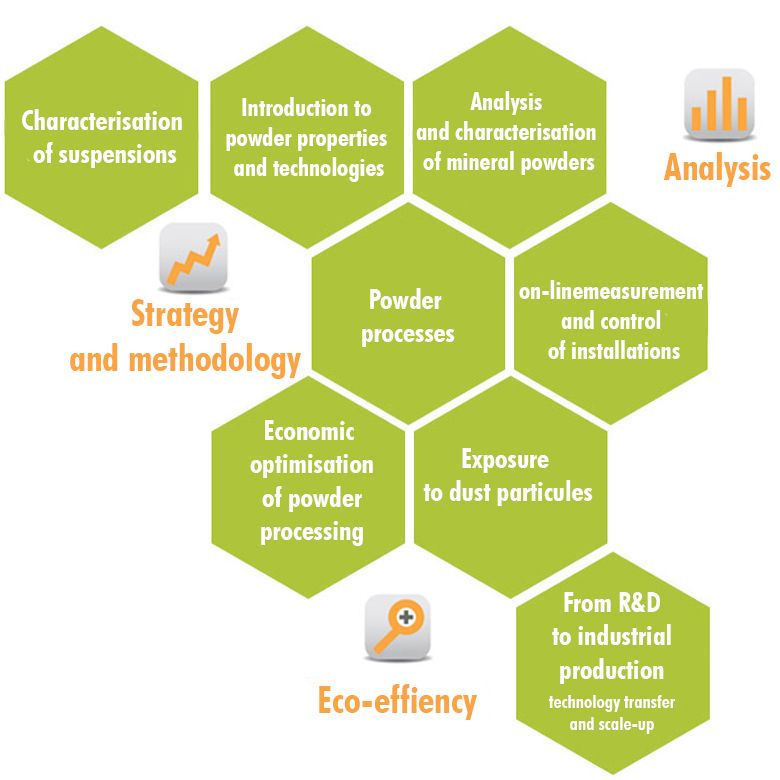

POUDRES DURABLES can provide you and your team with unique training courses, designed to address your specific needs within the Mineral industry.

Find out more on our training courses in the field of divided solids :

Process and Production

Innovation, strategy and R&D

Powder analysis, control and characterization

Quality Hygiene Safety and the environment of powders

Overview of the world of powders